Hydrostatic tools HGx-7, HGx-20, HGx-23 and HGx-29

for plane and free-form surfaces as well as outside diameters

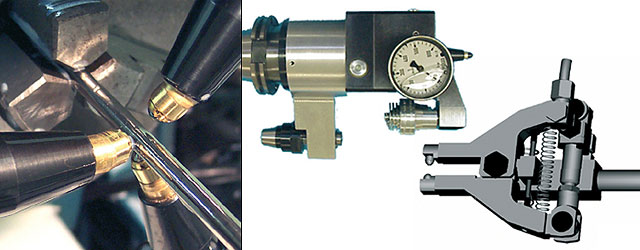

HGx-7

- For roller burnishing and deep rolling plane and free-form surfaces on machining centers and milling machines

- Machining of complex-shaped work pieces which were not able to be machined with the roller burnishing tools previously available

- Integral high-pressure pump; no feed line required

HGx-20

- Especially designed for external machining of thin cylinders (from 0.05 mm diameter) without additional support of the work piece to prevent flexing of the work piece

- Two static roller elements prevent the work piece from flexing; a third element burnishes or deep rolls the surface

- Provides consistent product quality because the rolling force is dependent on pressure and therefore simple to monitor.

HGx-23 (not illustrated)

- For machining cylinder and radii contours on axle journals

- The tool rotates the work piece is stationary.

- Provides consistent product quality, because the rolling force is dependent on pressure and therefore simple to monitor.

HGx-29

- For machining both sides of discs and thin-walled components such as turbine blades in a single operation

- For use on conventional and CNC machine tools

- Provides consistent product quality, because the rolling force is dependent on pressure and therefore simple to monitor.

Introduction | HGx1, HGx2, HGx4, HGx11 | HGx5 and HGx6 | HGx7, HGx20, HGx23, HGx29 |

HGx9, HGx10, HGx19 | mit FR-Rolle | Accessories DD | Accessories HGP | Back to product selection |